HISTORY

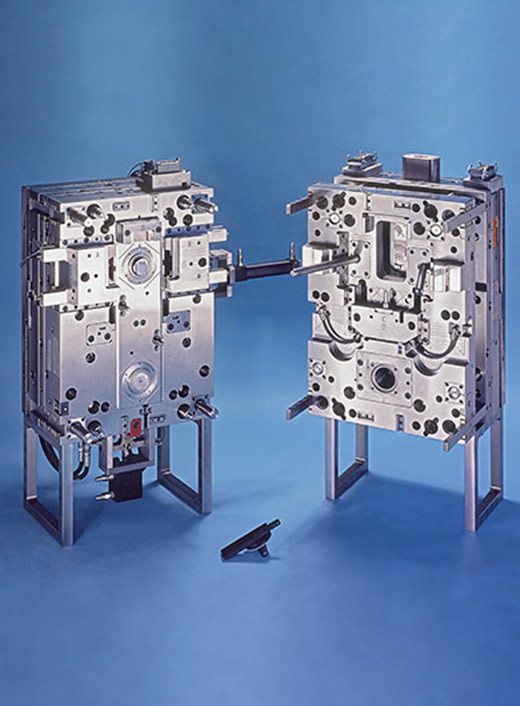

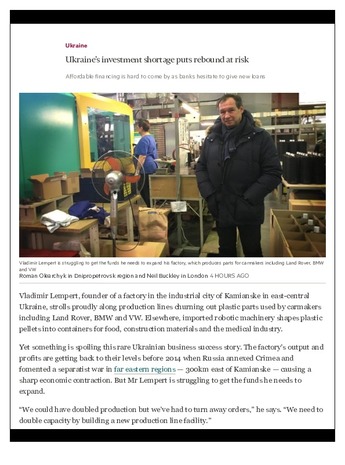

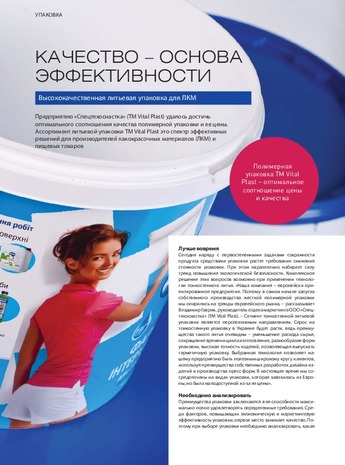

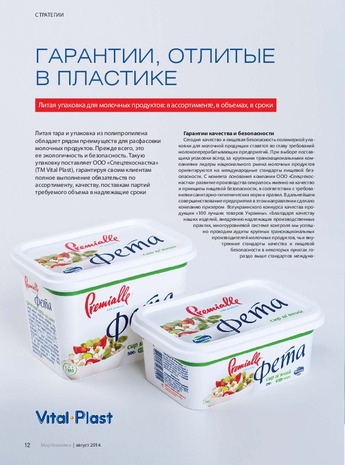

Spetztekhosnastka Ltd is a Ukrainian private company, founded in 1989 in the city of Dneprodzerzhinsk (now - the city of Kamianske) as an enterprise specializing in the production of stamps and molds. Over time, the company's activities have diversified, and today, in addition to manufacturing molds for molding plastic products, the company produces a large range of rigid plastic packaging for food and paint and varnish industry, and also, since 2008, plastic components for the production of European cars.

Among other activities of the company - the production of medical products, skeletons brake pads and the provision of household services to the population of the city of Kamianske.

1989

The founding of the production cooperative. We began operating on rented areas and with rented equipment.

1990

Starting of metalworking process, serial production of dies. The first major customer was the Russian company AvtoVAZ

1991

Joining of the city dry-cleaning factory to the manufacturing company Spetztekhosnastka

1992

Creation and registration of the Spetztekhosnastka logo, which is the current logo of the company to the present day

1998

Start of mastering of the production of injection molds. Acquisition of own territory - a production site in Bagley district

1999

Relocation to the new area. Purchase of machines that became the first property of Spetztekhosnastka

2001

Search for injection molding machines for conducting own mold testing. Purchase of 4 used machines from Germany. Start of the casting of plastic foodservice products

2002

Release of the first products of thin-walled casting. Certification of the production for compliance with the requirements of ISO 9001: 2000

2004

The first participation in the Euromold exhibition (Germany) and the presentation of the company on the international market. Start of the construction of new workshop for the production of plastic products

2005

Opening and launch of the production of plastic products in the new workshop. Purchase of new injection molding machines. Registration of the trademark “Vital Plast”. Formation of a shift production schedule and ensuring continuous operation of the workshop

2007

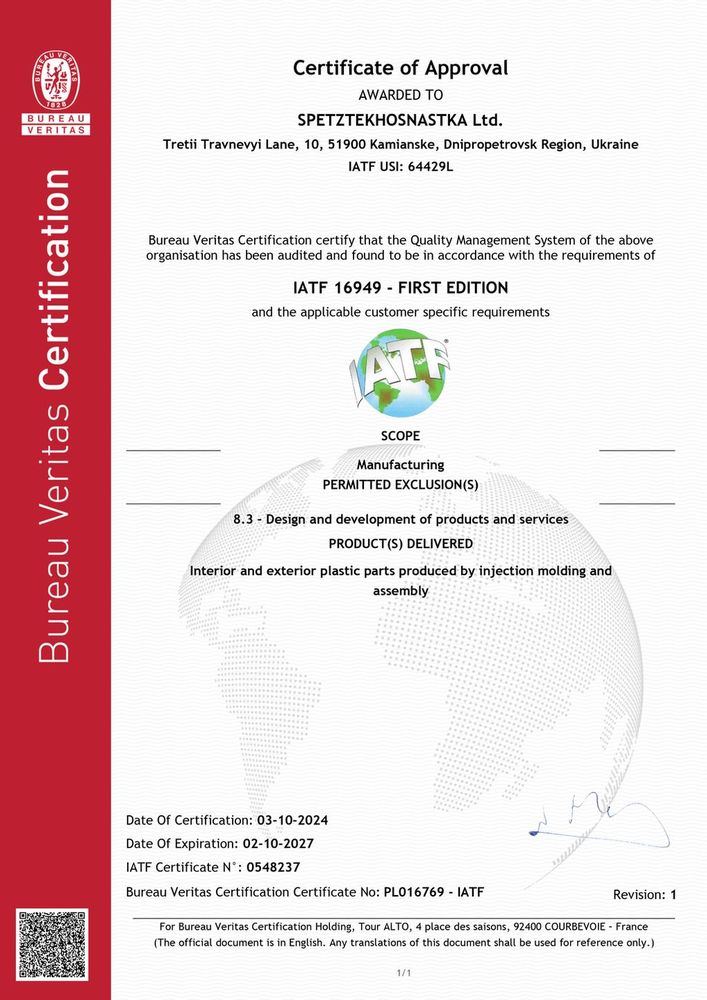

he first experience of automotive products moulding. Certification of the production for compliance with the requirements of ISO / TS 16949

2009

Purchase of the first robot for applying IML labels to plastic products

2010

Opening of the workshop for the production of automotive products. Certification of the production for compliance with the requirements of ISO 14001

2012

The launch of the new project for the production of plastic components for the Volkswagen Golf 7

2013

Purchase of the injection molding machine for two-shot moulding of plastic products

2014

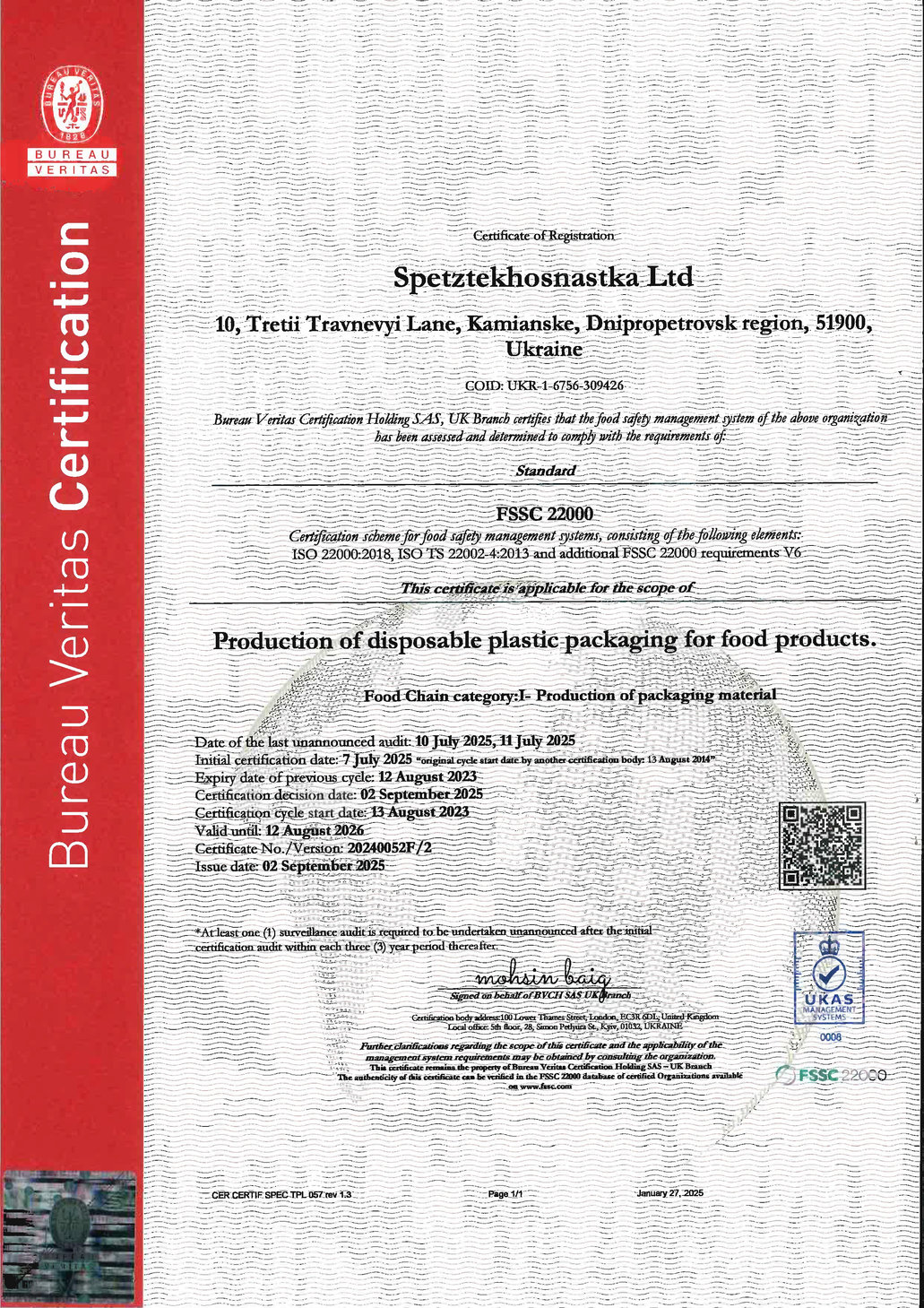

Certification of the production of plastic products for compliance with the requirements of the standard ISO 22000 - food industry. Implementation of the HACCP System

2015

Start of work with new SAN material (STYRENE-ACRYLONITRILE) in the manufacture of containers and packaging for the food industry

2017

Obtaining of international award - certificate of impeccable quality for outstanding innovations in production automation from the company Premium Sound Solutions (Belgium)

2018

Certification of the production of engineering plastics for compliance with the requirements of IATF16949 standard - updated version for the automotive industry

2020

Certification of the food safety management system at Plastic Packaging Production for compliance with the requirements of the FSSC 22000 certification scheme